منتجات

ELECTRONIC FLASHER RELAY OF ASSEMBLY LINE

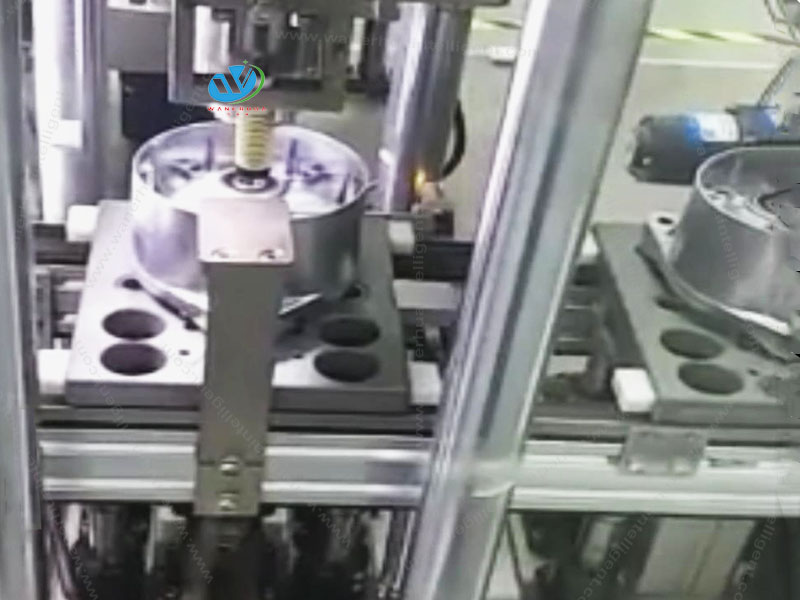

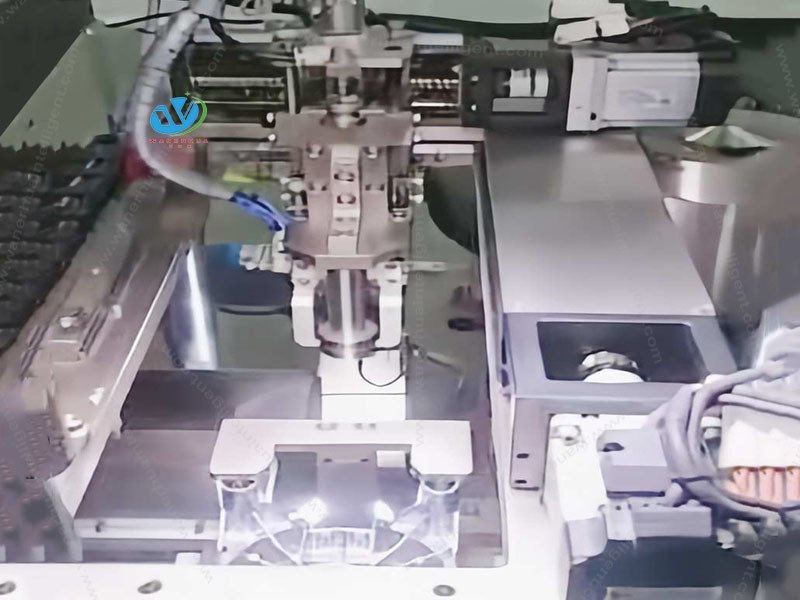

This production line successively completes the assembly of all parts of relay including coil, iron core, yoke, moving spring, base plate, resistance, terminal, stop piece, shell and other parts, and carries out the inspection of all electrical parameters of the assembled products, selects the defective products found in the assembly and inspection process, and finally outputs the qualified finished products. This production line realizes the full automatic production of relay, reduces the labor cost and improves the production efficiency.

رقم الصنف :

WEH – R53-135النظام (موك) :

1كفاءة العمل: :

500 - 700 PCS / Hدفع :

T/T, L/Cأصل المنتج :

Xiamen, Chineلون :

Geryميناء الشحن :

Xiamenفترة إنتاج :

Negotiationثقل :

Based on actual situationELECTRONIC FLASHER RELAY OF ASSEMBLY LINE

Lead Time:

|

Quantity (sets) |

1 - 1 |

> 1 |

|

Lead time (days) |

100 |

To be negotiated |

ASSEMBLY LINE ELECTRONIC COMPONENT RELAY MACHINE

Assembly Line Electronic Component Relay Machine, if you are looking to automate assemble line even further, Wanerhua has experience development, design, manufacturing, sales, service, technical training with customized electronic components relay automatic assembly equipment, and vision to confirm reducing labor demand, improving product qualificating rate, improving production efficiency and increasing enterprise profits. Wanerhua can be designed and customized for customers, to a greater extent to meet the technical needs of different.

Relay Line Production for Relay Electronic Component

The automatic assembly machine for relay can achieve automated production of multiple type relays assembly. From part loading, loading, sorting, orientation, quality inspection, transportation, packaging, fully customized automated assembly line, reducing labor demand, improving product qualification rate, improving production efficiency, and increasing enterprise profits.

Relay Working of Automatic Assembly Line

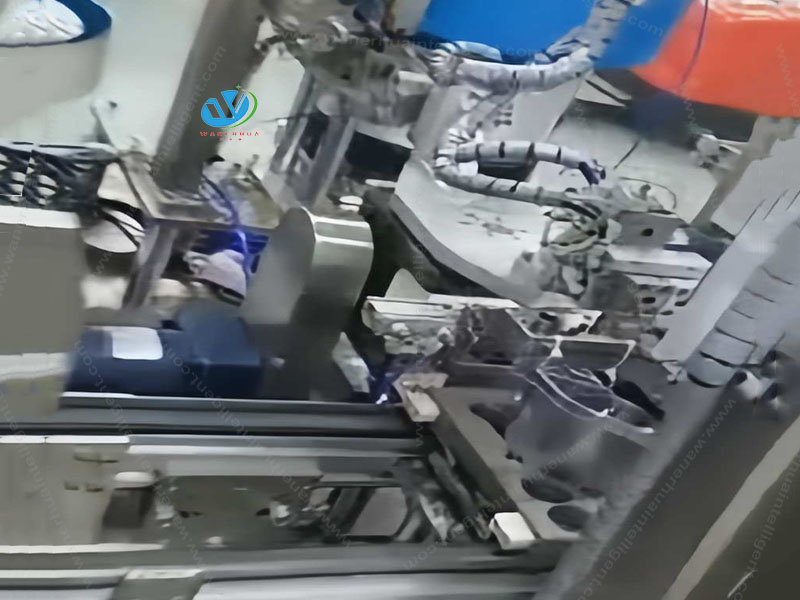

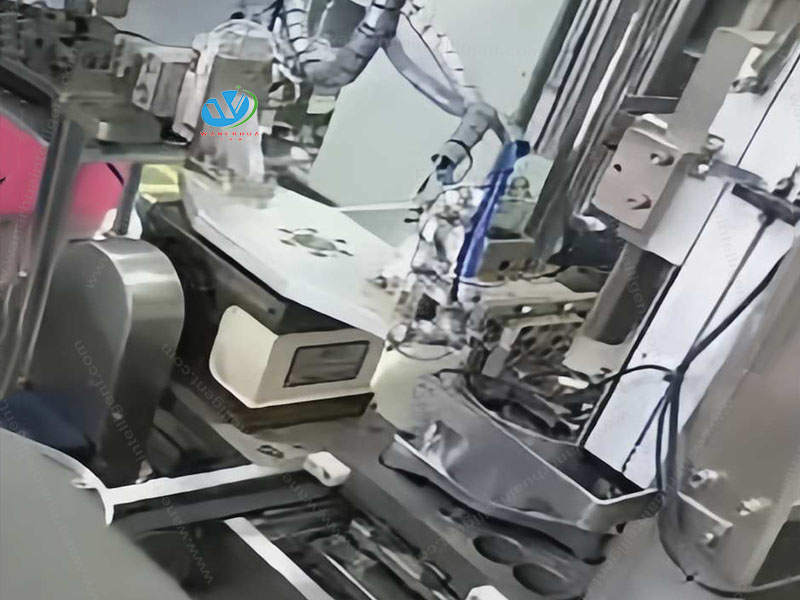

A specific relay assembly line, which mainly consists of multiple machines, all of which are connected in series. The means of transport are transported by pipelines and streamlines. The whole line is controlled by PLC, and each machine has a separate router for an independent LAN, which can ensure the stability of the whole system.

1. The linear structure is simple and easy to install and maintain.

2. Operating parts adopt parts of world famous brands.

3. Highly automated and intelligent operation, no pollution.

Technical Parameters:

|

Work efficiency |

800 -1000 pcs/hour |

|

Applicable power supply |

220VAC, 50HZ |

|

Equipment power |

6000W |

|

Applicable air source |

0.50~0.80Mpa (0.50Mpa is the best) |

|

Warranty period |

One year |

|

Additional services |

Professional English technology training |

|

Brand of Main Parts |

SMC Japan, SIEMENS Germany, Panasonic Japan,Keyence Japan, Schneider France, BASLER Germany, HIWIN Taiwan. |

1、PLC control system.

2、Automatic counting and output setting.

3、Touch screen, simple operation, and safety.

4、Fully automatic feeding and assembling. Automatic riveting, AB foot assembling, reed loading, electrical inspection, dust removal shell, laser marking, and collect plates. Auto-start / stop when there is material (or no material) detected. Detect parts presence, the good products and NG products will be unloaded separately.

5、All steel parts of the machine are chrome-plating, and all aluminum parts are anodized.

6、Automatic alarming in case of abnormal shutdown and reporting abnormal information.

Q: 1、Are you a factory or trading company?

A: We are an CE and ISO proved manufacturer specialized in automation equipment R&D and manufacturing in the fields of switches, motors, cooling fans, medical and other industrial areas since 2007.

Q: 2、How can we get the proposal and quotation sheet for automation equipment as our request?

A: Pls kindly supply us the following details as below:

2D/3D product drawings.

Capacity request.

Surface treatment requirements.

Samples send to our address for engineer evaluating.

After all information obtained, We will try to send you the proposal for confirmation within one week!!!!!

As soon as you confirm our proposal, we will send you the formal quotation sheet ASAP.

Q: 3、Where is your factory located?

A: Our factory is located in Xiamen, Fujian, China. Warmly welcome your visit to our factory. As soon as your schedule settle down, we can arrange our driver to pick up you if it's necessary.

Q: 4、How long is the warranty of your equipment?

A: One year warranty after receipt check upon delivery. And we will comprehensively provide you all kinds of technical support services in after-sale! And also, our engineers are available to service machinery overseas to do help until the machine is in good performance.

Q: 5、What is packing of this machine? Is it suitable for shipment?

A: Machine will be wrapped with shrink film to avoid any scartches, the outside packed by standard wooden case. It is suitable for shipment. After you receive machine, it's better to carefully check the overall appearance of machine. Your comments back will be highly appreciated.

Q: 6、How about payment terms and lead time:

A: a、50% deposit upon the contract, balance against check and acceptance before shipping.

b、It's around 10-20 days after deposit paid.

(The lead time can be negotiated according to specific situations)

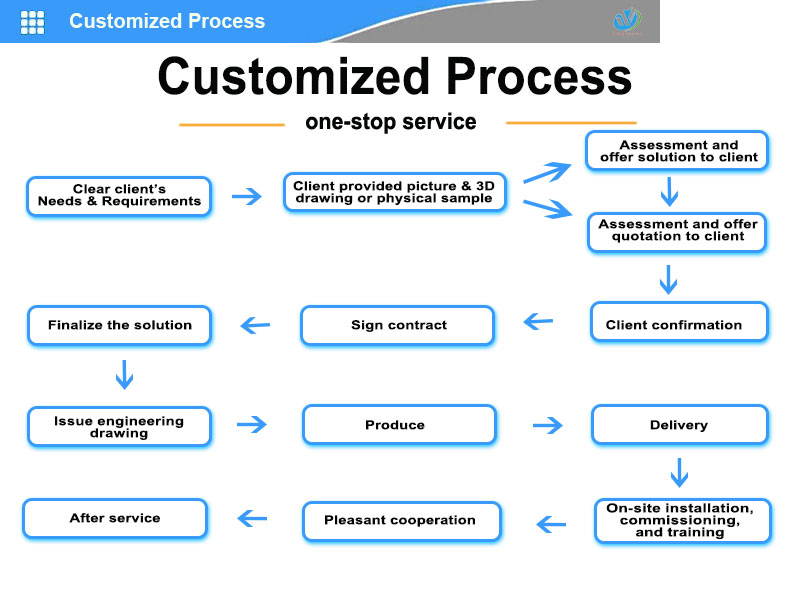

Customized Process:

Packaging and Logistics:

شركة وانيرهوا (شيامن) للآلات الذكية المحدودة. الذي يكرس جهوده للبحث والتطوير وتصنيع مجموعات مولدات الديزل منذ إنشائها في عام 2012 برأس مال مسجل قدره 47 مليون دولار أمريكي،

Add : Office Add: Rm. 1514, No. 345 Jiahe Rd, Siming District, Xiamen, Fujian, China, Code: 361001

Factory Add 1: 1/F, No.3 Zhongwan Road, Xingbei Industrial Zone, Jimei District, Xiamen2, China 361022

Factory Add 2: Unit 303, No. 21, Kengping Rd. Guankou Town, Jimei District, Xiamen City,Fujian, China 361023

البريد الإلكتروني : wanerhuaxue@gmail.com

حقوق النشر

2025@ Wanerhua (شيامن) ذكي الماكينات والشركة المحدودة

خريطة الموقع

| المدونة

| Xml

| سياسة الخصوصية

الشبكة المدعومة

الشبكة المدعومة

Friendly Links : Custom Crystal Oscillators AC Drive Manufacturer Variable Frequency Drive Hydraulic Welding Machine